Chromatic Dispersion in Optical Fibers

Beginning:

Telecommunications service providers have to face continuously growing bandwidth demands in all networks areas, from long-haul to access. Because installing new communication links would require huge investments, telecommunications carriers prefer to increase the capacity of their existing fiber links by using dense wavelength-division multiplexing (DWDM) systems and/or higher bit rates systems. However, most of the installed optical fibers are old and exhibit physical characteristics that may limit their ability to transmit high-speed signals. Dispersion is a consequence of the physical properties of the transmission medium.

What is Chromatic Dispersion ?

In an optical fiber, different colors of light travels at different speed. The blue light may run faster, and the red light may run slower. Even though they start at the same time in the beginning, they arrive at the destination at different times. This time delay is called chromatic dispersion. Here, "chromatic" stresses the fact that the time delay depends on the color difference, or wavelength difference between the lights.

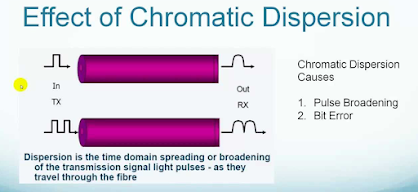

Effects of Chromatic Dispersion

The direct effect is light pulse broadening. A perfect pulse starts at the beginning. After it travels a length of fiber, may it be 100 meters, or 20000 meters, the light pulse becomes wider than the original signal. This is caused by chromatic dispersion. Because in the same pulse, the blue light travels faster, and the red light travels slower, so the total width of the pulse gets stretched wider.

Now let's look at above picture. Two perfect signals start at the beginning, but at the end, since both pulses get wider because of chromatic dispersion, they get overlapped to each other. If the overlap is too big, the detector may not be able to recognize these two signals and you get an error.

So chromatic dispersion causes pulse broadening and bit error.

Chromatic Dispersion types

Material dispersion:

This is because that the refractive index of silica, the material used to make optical fiber, is frequency dependent. So different frequency components, which means different wavelengths of light, travel at different speeds in silica. This is called material dispersion. Material Dispersion depends on the material's built-in refractive index and we cannot change that.

Wave guide dispersion

The light pulse travels partly in the core and partly in the cladding of the fiber. Light travels slower at the core, and faster at the cladding. The overall speed depends on the proportion of power that is distributed in the core and cladding. However, the power distribution itself is a function of the wavelength. The longer the wavelength, the more power in the cladding. So different colors of light travels at different speed because of different power distribution in the core and cladding. This phenomenon is called wave guide dispersion.

Since we can change the fiber's refractive index profile, we can engineer the wave guide dispersion to make specialty fibers. The total chromatic dispersion is the sum of material dispersion and wave guide dispersion.

Comments

Post a Comment